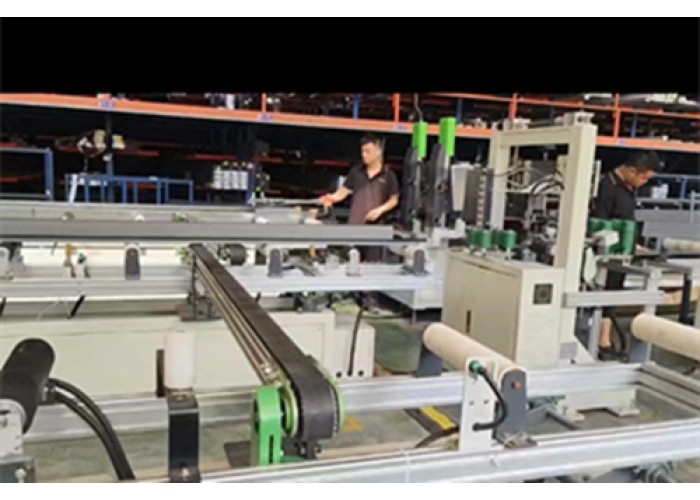

GKC-CNC-02 Seven-axis knurling machine (bottom knurling)

Features:

1)The knurling disc is under the profile, and the rubber roller is above, which can conveniently knurl the upper aluminum profile of the thrmal break profile .

2) knurling discs and clamps, to realize the top and botom knurling, can knurl and insert special double grooves aluminum profile, knurling efficiency has been improved by one time.

3) CNC adjust the rubber roller height to match aluminum profiles of different heights, or manually fine tuning left & right , up & down .

4)CNC adjust the knurling disc width , height of two clamps , height of total machine .

5) Advanced 15.6 inch interface, equipped with special software developed by ouselves. It can realize data storage and recall when changing different aluminum profiles.

6)Italy CAKMOTORI motor reducer, Schneider electric appliances, Siemens or Mitsubishi main frequency converter, Mitsubishi CNC PLC module, Yaskawa Servo motor, Airtac pneumatic,et

Technical parameters

|

Model No. |

GKC-CNC-02 |

|

Voltage |

380V/50Hz |

|

Total power |

2.78Kw |

|

Knurling disc diameter |

80mm |

|

Kunrling adjust range |

Horisontal (width):200 mm |

|

Vertical(height):200 mm |

|

|

Strip clamps adjust range |

12---63mm ( for insulation strips) |

|

Knurling speed |

0-110m/Min |

|

Max process size |

200x200mm(WxH) |

|

Knurling disc adjust width |

0-200mm |

|

Machine size |

1500x1100x1900mm(LxWxH) |

|

Machine weight |

900Kg |

Thermal Break Strip Insertion Machine For Aluminium Profile

views:2974

views:2974